Showroom

Abrasives are versatile materials used to shape or finish workpieces through rubbing, creating a scouring effect that removes dirt firmly attached to a surface. They come in various forms, including powders, liquids, and coated abrasives, each with different compositions and applications. Abrasives are essential in industries like metalworking, automotive, and construction, offering high-quality finishes and efficient operations.

CNC Tooling is a comprehensive range of high-precision cutting tools designed for Computer Numerical Control (CNC) machining. These tools are engineered to deliver exceptional performance, accuracy, and efficiency in a wide range of CNC applications. Featuring advanced geometries and coatings, CNC Tooling ensures superior surface finishes, extended tool life, and reduced machining times.

Carbide Drills are cutting tools designed for drilling holes in materials such as metal, wood, and plastic. Manufactured using tungsten carbide, these drills offer superior hardness, wear resistance, and toughness compared to high-speed steel (HSS) drills.

High-Speed Steel (HSS) Drills are a versatile and cost-effective solution for drilling holes in a variety of materials. These drills are made from high-quality HSS alloy, providing a balance of hardness, toughness, and wear resistance. HSS Drills feature a range of point geometries and flute designs to suit different materials and applications.

Measuring Instruments are precision tools used for accurately measuring and inspecting various dimensions, angles, and surfaces. These instruments include micrometers, calipers, dial indicators, and coordinate measuring machines (CMMs).

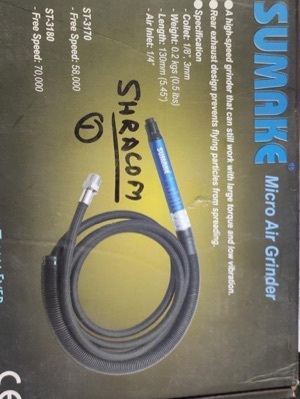

Pneumatic Grinders are handheld power tools that use compressed air to drive a grinding wheel or abrasive disc. These grinders are lightweight, compact, and ideal for grinding, deburring, and finishing operations in confined spaces or hard-to-reach areas.

Rotary Tables are precision machine tool accessories used for indexing, positioning, and holding workpieces during machining operations. These tables feature a rotating platform that can be precisely controlled and locked in position.

CNC Tool Holders are devices used to securely hold cutting tools in CNC machines. They provide a stable and accurate interface between the tool and the machine spindle, ensuring precise and consistent tool positioning. CNC Tool Holders come in various types, such as collet chucks, hydraulic chucks, and shrink-fit holders, each with its own advantages in terms of runout, clamping force, and tool change speed.

Tungsten Wear Parts are highly durable and wear-resistant components designed for industrial applications. Manufactured from pure tungsten carbide, these parts offer exceptional hardness, strength, and abrasion resistance. With over 10 years of experience in carbide production, our professional team ensures fast delivery of customized, polished tungsten carbide wear parts.

"We Only Deal In End User"